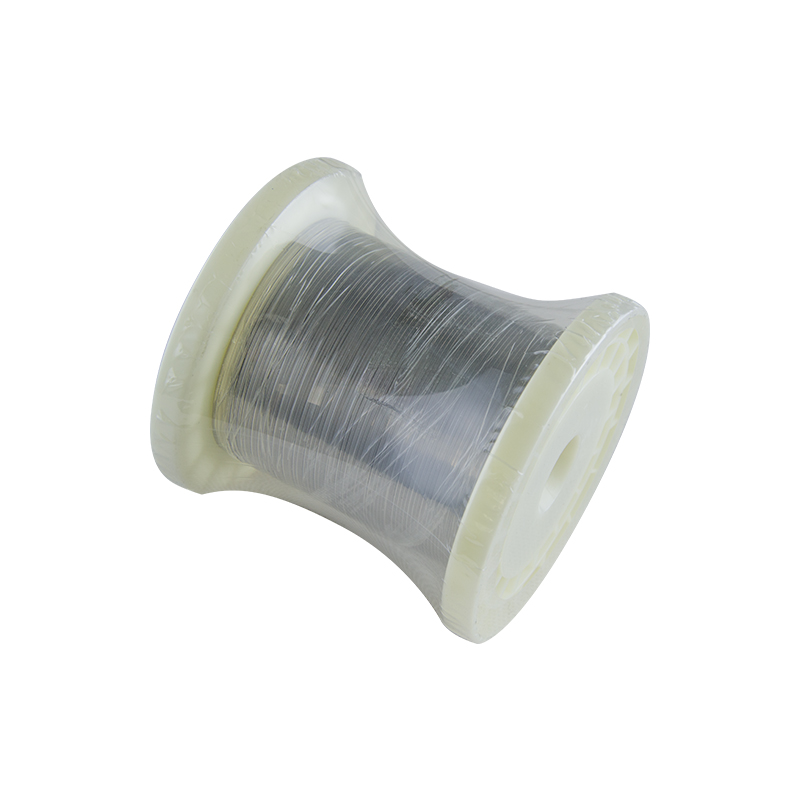

FeCrAl alloy 0cr23al5 Resistance Heating Flat Wire nga adunay ISO9001 Certificate

0cr23al5 Resistance Heating Flat Wire nga adunay ISO9001 Certificate

Resistance Wire nga hinimo gikan sa Nickel Chrome Alloys, Nickel Chrome Iron Alloys, Iron Chrome Aluminum Alloys, Copper Nickel Alloys.

Panguna nga gigamit sa heater, heating element ug resistor, ug uban pa.

NiCr 80/20, NiCr 70/30, NiCr 60/15, NiCr 35/20

FeCrAl15-5, FeCrAl20-5, FeCrAl 25-5, ug uban pa…

Constantan, Alloy 30, Alloy 60, Alloy 90, ug uban pa.

Resistivity sa Elektrisidad gikan sa 0.02 u ohm/m-1.53 u ohm/m

Temperatura sa Pag-operate gikan sa 200 C hangtod 1400 C

Pls gawasnon nga kontaka kami kung adunay bisan unsang pangutana.

NiCr:

RESISTOHM 20, RESISTOHM 30, RESISTOHM 40, RESISTOHM 60, RESISTOHM 70, RESISTOHM 80

FeCrAl:

RESISTOHM 125, RESISTOHM 135, RESISTOHM 140,

RESISTOHM 145, RESISTOHM 153

CuNi

Constantan, Cuprothal 5, Cuprothal 10, Cuprothal 15, Cuprothal 30, Eurica

| Grado sa FeCrAl Alloy | Komposisyon sa Kemikal % | |||||||||

| C | P | S | Mn | Si | Cr | Ni | Al | Fe | Re | Ang uban |

| kinatas-an (≤) | ||||||||||

| 1Cr13Al4 | 0.12 | 0.025 | 0.025 | 0.7 | ≤1.00 | 12.5-15.0 | —- | 3.5-4.5 | 0.1 | Bal. |

| 0Cr15Al5 | 0.12 | 0.025 | 0.025 | 0.7 | ≤1.00 | 14.5-15.5 | —- | 4.5-5.3 | 0.1 | Bal. |

| 0Cr25Al5 | 0.06 | 0.025 | 0.025 | 0.7 | ≤0.60 | 23.0-26.0 | ≤0.60 | 4.5-6.5 | 0.1 | Bal. |

| 0Cr23Al5 | 0.06 | 0.025 | 0.025 | 0.7 | ≤0.60 | 20.5-23.5 | ≤0.60 | 4.2-5.3 | 0.1 | Bal. |

| 0Cr21Al6 | 0.06 | 0.025 | 0.025 | 0.7 | ≤1.00 | 19.0-22.0 | ≤0.60 | 5.0-7.0 | 0.1 | Bal. |

| 0Cr21Al4 | 0.06 | 0.025 | 0.025 | 0.7 | ≤1.00 | 21.0-23.0 | ≤0.60 | 3.0-5.2 | 0.1 | Bal. |

| 0Cr21Al6Nb | 0.05 | 0.025 | 0.025 | 0.7 | ≤0.60 | 21.0-23.0 | ≤0.60 | 5.0-7.0 | 0.1 | Bal. |

| 0Cr27Al7Mo2 | 0.05 | 0.025 | 0.025 | 0.7 | ≤0.40 | 26.5-27.8 | ≤0.60 | 6.0-7.0 | 0.1 | Bal. |

![]()

![]()

![]()

![]()

Komposisyon sa Kemikal ug mga Kabtangan:

| Mga Kabtangan/Grado | NiCr 80/20 | NiCr 70/30 | NiCr 60/15 | NiCr 35/20 | NiCr 30/20 | |

| Pangunang Kemikal Komposisyon (%) | Ni | Bal. | Bal. | 55.0-61.0 | 34.0-37.0 | 30.0-34.0 |

| Cr | 20.0-23.0 | 28.0-31.0 | 15.0-18.0 | 18.0-21.0 | 18.0-21.0 | |

| Fe | ≤ 1.0 | ≤ 1.0 | Bal. | Bal. | Bal. | |

| Labing Maayong Pagtrabaho Temperatura (ºC) | 1200 | 1250 | 1150 | 1100 | 1100 | |

| Resistivity sa 20ºC (μ Ω · m) | 1.09 | 1.18 | 1.12 | 1.04 | 1.04 | |

| Densidad (g/cm3) | 8.4 | 8.1 | 8.2 | 7.9 | 7.9 | |

| Konduktibidad sa Init (KJ/m· h· ºC) | 60.3 | 45.2 | 45.2 | 43.8 | 43.8 | |

| Koepisyent sa Thermal Pagpalapad (α × 10-6/ºC) | 18 | 17 | 17 | 19 | 19 | |

| Punto sa Pagkatunaw (ºC) | 1400 | 1380 | 1390 | 1390 | 1390 | |

| Pag-inat (%) | > 20 | > 20 | > 20 | > 20 | > 20 | |

| Mikrograpikong Istruktura | austenite | austenite | austenite | austenite | austenite | |

| Magnetikong Kabtangan | dili magnetiko | dili magnetiko | dili magnetiko | dili magnetiko | dili magnetiko | |

![]()

![]()

![]()

![]()

| Grado sa CuNi Alloys | Resistivity sa kuryente (20 degreeΩ mm² /m) | koepisyent sa temperatura sa resistensya (10^6/degree) | Densidad g/mm² | Pinakataas nga temperatura (grado) | Punto sa pagkatunaw (grado) |

| CuNi1 | 0.03 | < 1000 | 8.9 | 200 | 1085 |

| CuNi2 | 0.05 | < 1200 | 8.9 | 200 | 1090 |

| CuNi6 | 0.10 | < 600 | 8.9 | 220 | 1095 |

| CuNi8 | 0.12 | < 570 | 8.9 | 250 | 1097 |

| CuNi10 | 0.15 | < 500 | 8.9 | 250 | 1100 |

| CuNi14 | 0.20 | < 380 | 8.9 | 300 | 1115 |

| CuNi19 | 0.25 | < 250 | 8.9 | 300 | 1135 |

| CuNi22 | 0.30 | < 160 | 8.9 | 300 | 1150 |

| CuNi30 | 0.35 | < 100 | 8.9 | 350 | 1170 |

| CuNi34 | 0.40 | -0 | 8.9 | 350 | 1180 |

| CuNi40 | 0.48 | ± 40 | 8.9 | 400 | 1280 |

| CuNi44 | 0.50 | < -6 | 8.9 | 400 | 1280 |

![]()

![]()

![]()

![]()

Mga kategorya sa produkto

-

Telepono

-

E-mail

-

Whatsapp

-

WeChat

Judy

150 0000 2421

-

Ibabaw